Butterfly valve, also known as butterfly valve, is a type of industrial valve used to regulate the flow of fluid in pipelines. The way a butterfly valve works is based on the opening and closing of a rotating butterfly wing to control flow – similar to a ball valve.

Nội dung

General structure of butterfly valve

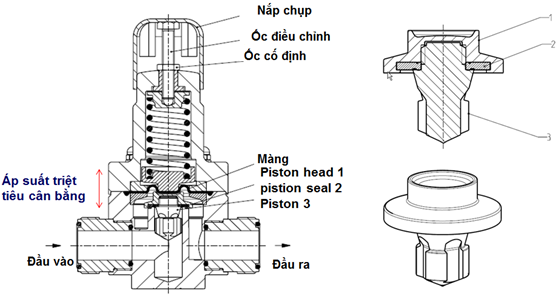

The structure of the butterfly valve includes the following components:

Valve bodies are made from metal castings or according to the specific requirements of the application. With convenient bolt and nut mounting holes, the valve body makes installation easy. Using materials such as steel, cast iron and stainless steel, the valve body helps your system operate stably and safely. Guaranteed performance with quality products from us!

Valve disc: Has a shape similar to a butterfly wing and is used to regulate flow through a lever or crank mechanism. Valve discs are usually manufactured from cast iron, steel or stainless steel.

Sealing gasket (seat): Used to create tightness between the valve disc and valve body. Common seat materials include EPDM, PTFE, and Hi EPDM rubber.

Lever or crank (steering wheel): Plays an important role in adjusting the opening of the valve disc to control flow. They create different opening angles to change the flow.

Other parts: In addition, butterfly valves also include parts such as shafts, positioning gears and bolts to ensure stable and reliable operation.

The detailed structure of the butterfly valve may vary based on the specific intended use and technical requirements of the application.

Operating principle of butterfly valve

As you can see in the picture below, when fully closed, the valve disc will lie parallel to the valve body, creating a horizontal barrier that prevents fluid from entering. When thrust is applied through a control device, such as a rocker arm or handwheel (automatic electrical or pneumatic control), the force is transmitted to the valve shaft and disc. This results in rotation of the valve disc, opening the gate and allowing fluid to flow through the valve at a rate depending on the opening angle of the valve disc. The fully open state corresponds to placing the opening angle of the valve disc perpendicular to 90 degrees compared to the valve body.

Classification of Butterfly Valves

Để phân loại, ta có thể dựa trên các đặc điểm và tiêu chí như: kết nối kiểu, vật liệu, kiểu truyền động…

1. Classification by connection type

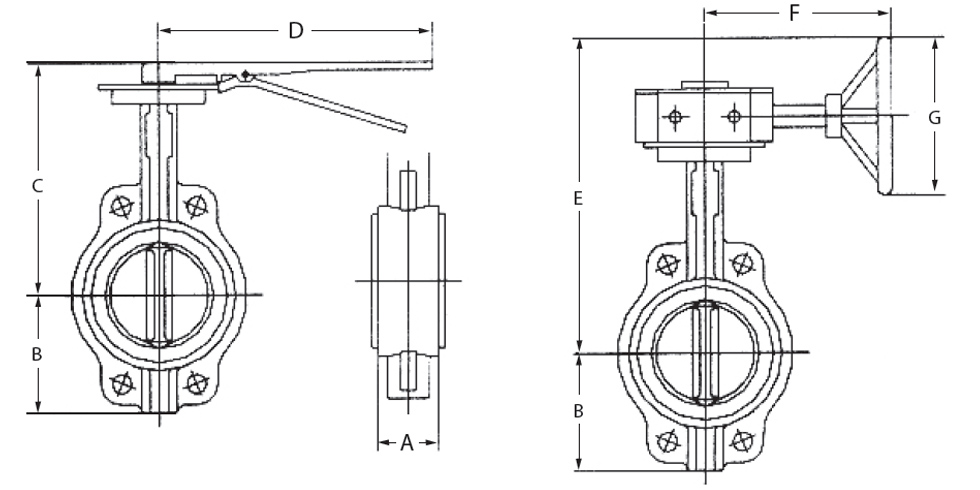

- Butterfly valve with flange connection: On the valve body there are two flanges on both sides. Each flange is connected to the pipe flange via a separate set of bolts and screws.

- Lug connection butterfly valve: On the valve body there are lugs to pass through the bolts. A set of long bolts will be installed through the hole in both the lug and the two flanges to clamp the valve tightly to the pipe.

- Wafer connection butterfly valve: This type also uses a set of long bolts similar to the Lug connection valve, but the valve body does not position itself but depends on the pressure from the two flanges of the two pipe ends on both sides. The valve body has no flanges or bolt lugs, only pairs of holes, making installation easier.

These connection types are selected depending on the specific requirements of the application and the desired installation.

2. Classification according to valve manufacturing material

- Cast iron butterfly valve: This is the most common type of valve and is manufactured entirely from cast iron. Often applied in projects related to water supply and fire protection systems.

- Steel butterfly valve: This type is often used in applications with high pressure and temperature, such as hot oil or saturated steam pipeline systems.

- Stainless steel butterfly valves 304, 316 (stainless steel): They are often applied in raw wastewater treatment systems and in dilute chemical applications.

- Plastic butterfly valve: This type is suitable for pipeline systems used to transport chemicals. The choice between plastics such as PVC, UPVC, PP depends on the specific chemical, concentration and temperature of the application.

3. Classification by transmission type

3.1 Butterfly valve

Van thường sử dụng cho hệ thống đường ống có đường ống kính có nghĩa nhỏ hơn 250mm, với sức mạnh trong đường ống nhỏ hơn 16k.

3.2 Hand crank butterfly valve

Valves are often used for pipeline systems with large nominal diameters, with high pressure in the pipeline.

3.3 Linear control butterfly valve

Advantages of butterfly valve:

- Lightweight and Compact Design: This valve is designed to be lightweight and compact, perfect for maintenance requirements in limited spaces. Installation, disassembly and repair are easy and convenient.

- Simple installation and operation: Installation and operation of this type of valve is very easy, saving time and effort.

- Common use: This is a popular type of industrial valve that is widely used in factories and plants today.

- Variety of sizes: This type of valve is available in many different sizes, suitable for all existing pipe sizes.

- Diverse connection types: This type of valve has many different connection types, making the installation process quick and convenient.

- Replaceable sealing ring: This valve has the ability to replace the sealing ring during use, helping to solve technical problems conveniently and effectively.

Application of butterfly valve

Butterfly valves can be used for a variety of applications. They perform well in large pipeline water supply applications and slurry applications. Below are some typical applications of butterfly valves:

- Cold water, air, gas, fire…

- Slurry, slurry and vacuum

- High temperature and high pressure water and steam

- Pneumatic or pneumatic applications

Note when choosing Butterfly Valve

Before deciding to buy, it is extremely important to check the valve parameters and performance compared to the intended application:

- Material Compatibility: Make sure that the material of the seal ring, disc and valve body matches the properties of the fluid in the piping system you are installing.

- Temperature and Pressure: Determine the valve’s operating temperature and maximum pressure to ensure that they meet the requirements of the specific system you are installing.

- Other Operating Conditions: Media characteristics, flow rate and viscosity are also important factors to consider.

- Follow Specifications: Do not exceed the conditions under which the valve is designed to operate. This will ensure the performance and durability of the valve.

- Restrictions on Use for Hot Steam: Please note that the valve should not be used for hot steam applications, and observe recommendations and restrictions regarding the type of fluid and operating conditions of the valve.